How to Rebuild Your Materials Requisition Process Kojo Blog

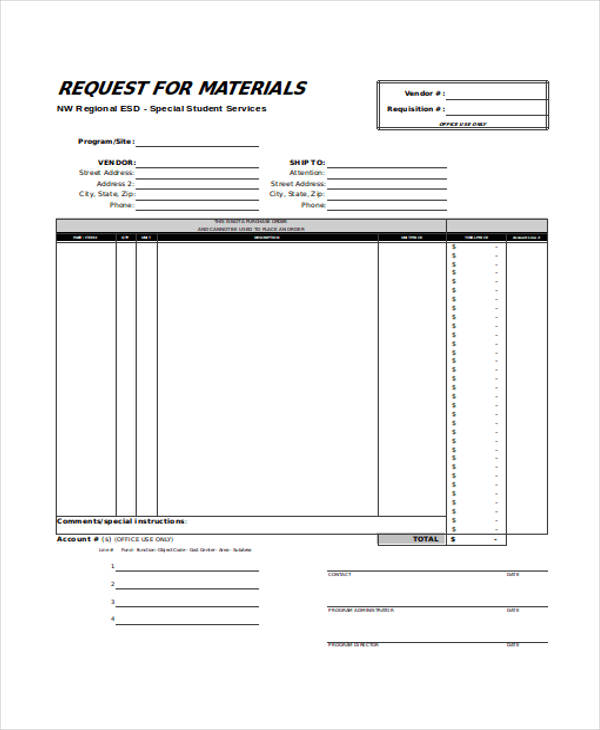

We also have other Service Requisition Form that are used for other types of requests, not just materials and items needed for a project or service. Typically, this form has the job number, the date of the request, the date the items are needed by, material description, item number, quantity, and proper management signatures for approval. Once the goods are transferred from storage to production the raw materials account is credited and the goods in process inventory account is debited. A Dental Supply Order Form is a form template designed to streamline the procurement process for dental practices and clinics. Material requisition is a vital piece of construction planning, giving your teams the tools they need to complete each job. However, it can go off the rails quickly if you don’t have clean processes in place, leading to miscommunication and wasted time and money.

Book Supply Order Request Form

If you’d like to accept payments online, integrate your supply order form with a payment gateway — Jotform offers more than 30 trusted providers to choose from. When you’re done customizing, simply publish your Supply Order Form on your company website. By making it easier to request supplies online, your customers won’t have to worry when they run out of the resources they need. Unless a service invoice is to be prepared from this document, it usually does not include item costs or prices. The supplier receives the order, and if accepted, contracts with the purchaser for the products requested.

PROCUREMENT

Avoid the roadblocks and implement the right tools and best practices to streamline requisitions. Read our e-book, 7 Steps to Better Procurement for Specialty Contractors, for deeper insights into requesting and procurement as a whole. Countless roadblocks can obstruct the requisition process depending on the job, your team, and how you operate. Here are some of the most common mistakes to look for and what to do about them. Your operation needs accurate and timely material delivery to streamline procurement, but disorganization and communication breakdowns zap efficiency, accountability, and quality management.

Cleaning Supply Order Form

For example, an Equipment Requisition Form should clearly specify the type of equipment, model, brand, and any specific features required to meet the operational needs. Create a quick and easy Product Recall Response Form to efficiently gather essential details about recalled products and actions taken. Use this free template to streamline your recall process and ensure timely resolution. Embarking on the journey of material management requires a solid grasp of the Material Requisition Form. This complete guide, infused with practical examples, walks you through the nuances of effectively using a Requisition Form and Supply Requisition Form. Whether you’re replenishing office supplies or managing large-scale inventory, understanding the intricacies of these forms is essential.

“Material Requisition Forms” also found in:

- This team of experts helps Finance Strategists maintain the highest level of accuracy and professionalism possible.

- After receiving a materials requisition form, the store-keeper issues the required materials to the correct job and enters the details in the appropriate bin card.

- Unless a service invoice is to be prepared from this document, it usually does not include item costs or prices.

- Quickly gather essential information from your team, track audit details, and ensure smooth communication between departments.

- He has been the CFO or controller of both small and medium sized companies and has run small businesses of his own.

- It’s vital for managing Stock Requisition Form submissions, ensuring timely and efficient material allocation.

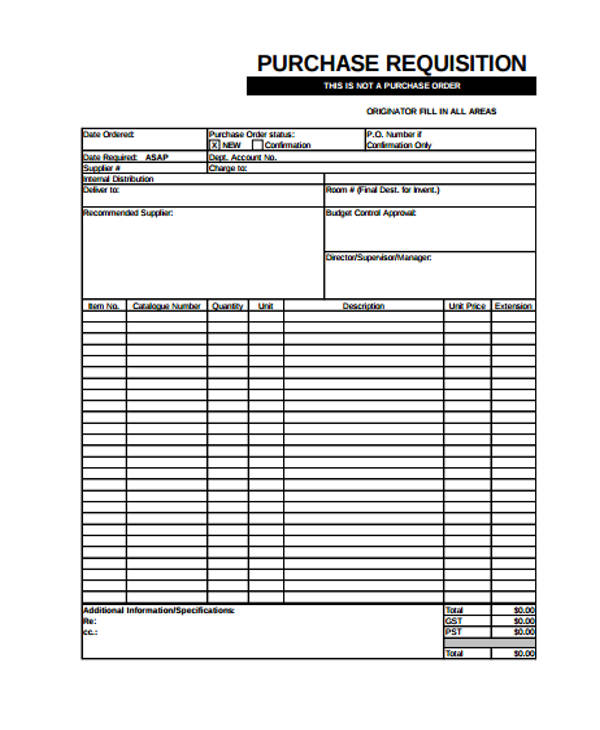

A purchase requisition form can be used for any type of purchase, while the material form is only used throughout the production process. First, it’s used to record the movement of materials throughout the manufacturing process. When the company orders goods, they are delivered to the storage facility and the appropriate forms are filled out. In conclusion, the material requisition form is a critical document that plays an essential role in inventory management and material procurement. It enables businesses to streamline their inventory management processes, ensure that they have the materials needed for their projects, and track inventory levels.

Four CFO Pain Points Every Construction Firm Should Eliminate

Use this free template to simplify your contract renewals and keep your business partnerships running smoothly. Streamline your analytics requests with our easy-to-use Business Analytics Request Form. Collect essential details such as data sources, analysis type, and reporting preferences effortlessly. Simplify the process of safeguarding your business operations by using our free, easy-to-follow template.

Quickly identify and address workplace hazards with this Hazard Report Form template. It includes fields for hazard details, potential risks, and immediate actions taken. Use this free template to enhance safety, improve hazard tracking, and ensure a secure work environment. Gather key details about your company, objectives, and criteria for potential partners effortlessly. If the materials have to be delivered, then a delivery address should be included on the Material Requisition Form as well.

Dive into this keyword-rich exploration to enhance your procurement process, ensuring you have the right materials at the right time for seamless operations. The form can be used as part of a job cost system to accumulate direct and indirect material costs for raw materials used in production for a particular job. On completion the material costs can be transferred to the job cost record template. You, 5 ways to reduce your taxes for next year however, will not see a material requisition form used in a computerized planning production environment. That’s because the picking information is sent to the warehouse as an electronic message in the system rather than making use of the form. The requisition form is also used to allocate production costs to goods in process, since not all inventories in process will finish in the current year.

At Finance Strategists, we partner with financial experts to ensure the accuracy of our financial content. One copy is sent to the store-keeper and another is retained by the initiating department for future reference. Once the requisition form is completed, it should be reviewed and approved by the appropriate personnel. This may include the inventory manager, the purchasing manager, or the finance department. Once approved, the form is forwarded to the inventory department for processing. Information on the requisition is used to update the stores record card, also known as the bin card, and the stores ledger.

Comments are closed.